LH-type Double Girder Overhead Crane (double-beam traveling crane) is mainly composed of four parts: electric hoist trolley, bridge frame, trolley operating mechanism and electrical control device. The lifting mechanism adopts a fixed wire rope electric hoist, and can also use a control room and There are two control forms: ground remote control, which is flexible and convenient to operate, safe and reliable; frequency conversion control can be added when necessary.

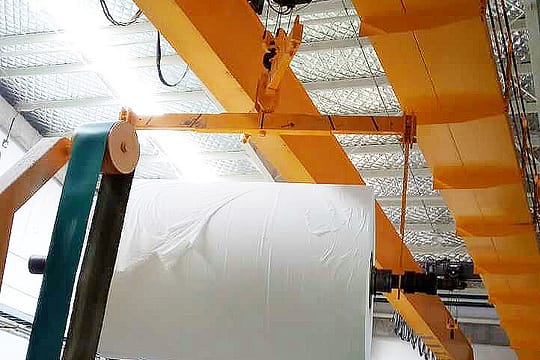

Clamp double girder overhead crane

QB explosion-proof double girder overhead crane

QY insulated double girder overhead crane

NLH — Double girder electric hoist overhead crane with European style design with a capacity of 3 ton -80 ton, with a lower profile than LH type.

LH— Double Girder electric hoist bridge crane with CD/MD wire rope hoist trolley, with a capacity of 3 tons -63 tons, a cheaper solution than NLH.

QDX — Double girder overhead crane with European style open winch trolley with capacity of 3 ton -320 ton lower headroom with QD type hook crane.

QD —Universal Double Girder Hook Overhead Crane for General Use with a capacity from 3-ton to 550-ton

QDY —Casting bridge crane for hot ladle handling with a capacity of 3 ton -74 ton

YZ — Double Girder Overhead Casting Crane with Capacity of 75 ton -320 ton

QZ— Grab bridge crane with double girder crane design with orange peel grab or clamshell grab bucket for bulk loads handling

QB— Explosion-proof bridge crane with explosion-proof design for hazardous applications with a capacity of 5 ~ 75 tons

QE— Double Girder bridge crane with Double Open Winch for Tandem Lifting with a capacity of f (2.5+2.5)~(200+200) tons

QY— Insulated double girder bridge crane for smelting workshops of electrolyzing nonferrous metal, aluminum, and magnesium with a capacity of 1 ton -50 Ton

QC— Electromagnetic Bridge Crane for steel meta handling, used in steel mill or steel scrap yard for steel scrap handling

QG— Hanging girder bridge crane for long and awkward load handling with lifting beam and lifting spreader

QL— Electromagnetic hanging beam bridge crane for long and heavy loads handling such as steel pipe, steel plate, etc.

SQ— Manual double girder crane for workshops or warehouses where there is a shortage of electric power or an explosion-proof crane is required.

| Item | Parameter |

| Standard Capacity | 5-32/5ton |

| Span length: | 10.5-31.5m |

| Lifting height: | 3-50m |

| Work duty | A3/A4 |

| Rated voltage | 220V~690V, 50-60Hz, 3ph AC |

| Crane control mode | Floor control / Remote control / Cabin room control |

| Work environment temperature | -25℃~+50℃, relative humidity ≤85% |

| Main Girder | The main girder is a box-shaped structure on the track. The section of the main girder is systematically analyzed and calculated using ANSYS finite element calculation method to ensure that it has sufficient strength, rigidity and overall stability. The camber of the main girder is (1~1.4) S/1000 , And the maximum camber position is controlled within 1/10 of the middle of the span. The main stress member of the main girders is Q255B, and the minimum plate thickness is not less than 6mm. | |

| End carriages | The end carriages are the box-shaped structure, and the connection between the end carriages and the main girders is the rigid connection. In order to facilitate transportation, the end carriages are disconnected and connected by high-strength bolts. Each connecting plate is positioned with reamed bolts, and the positioning check mark has been made at the factory. | |

| Platform and railings | The tread surface of the bridge platform is made of non-slip patterned steel plate with a thickness of 3mm. The channels of the bridge are equipped with railings with a height of 1050mm. The railings are equipped with horizontal crossbars with a spacing of 350mm. Any place can withstand 1kN (100kgf) load from any direction without plastic deformation. All railings are connected by stamping plates and bolts, realizing no welding on site. | |

| Lifting mechanism | The main and auxiliary lifting mechanisms are arranged on the same trolley frame, with independent driving devices for each mechanisms The working principle of the hoisting mechanism: the electric motor performs work, the speed is changed by the reducer, and then the drum is driven by the drum coupling, and the lifting hook is completed through the wire rope winding system. The hoisting mechanism adopts a series resistance speed control system, which has stable braking and small impact and accurate positioning of the hook, which not only improves the user's production efficiency, but also greatly extends the service life of the components of the hoisting mechanism. The components are compactly arranged and easy to maintain, ensuring safety and reliability. | |

| Trolley traversing mechanism | The trolley traversing mechanism of the trolley is supported by 4 wheels, and a set of independent driving system is adopted to drive the trolley in a centralized manner. When starting, the driving wheel does not slip, and when braking, it is stable and reliable. This structural arrangement is conducive to the installation, maintenance and disassembly of the components of the drive system. | |

| Crane traveling mechanism | The crane traveling mechanism is supported by 4pcs crane wheels, and two independent drive systems are used to drive the crane separately. The transmission type of the crane traveling drive system is: a motor drives a reducer through a gear coupling and a transmission shaft. The low-speed shaft of the reducer is connected to the wheel shaft with a coupling, and the driving wheel ratio is 1:2. When starting, the driving wheel does not slip, and when braking, it is stable and reliable. This structural arrangement is conducive to the installation, maintenance and disassembly of the components of the drive system. | |

| Hook group |  | Forged hook block The hook is a forged hook, hook material is DG20. The ratio of the pulley diameter to the wire rope diameter is greater than 20 to ensure the service life of the wire rope The pulley material is cast steel or nodular cast iron, the cast steel is no less than ZG310-570, and the performance of nodular cast iron is no less than QT400-18. |

| Coupling and transmission shaft |  | The coupling is safe and reliable, with good transmission performance The drive shaft is made of 45# steel, and the strength is strictly calculated. Ensure its reliable strength and smooth transmission torque. |

| Steel wire rope |  | The fiber core steel wire rope is soft and has good bending performance. It is strong toughness, non-absorption, resistance to extrusion, etc. The steel wire rope is not easy to be deformed, the diameter is uniform and stable. |

| Wheel group |  | The corner box type wheel sets are all led out by oil pipes, which is convenient for oiling and maintenance The wheel material adopts ZG340-640, and is subjected to advanced power frequency heat treatment and quenching |

| Brake | Adopt YWZ series hydraulic thruster type brake The braking is stable, safe and reliable, and the action frequency is high. | |

| Reducer |  |

|

| Motor |  | The electric motor is suitable for driving various lifting machinery and metallurgical auxiliary equipment. It has high overload capacity and mechanical strength. It is especially suitable for short-term or intermittent operation, frequent starting, braking, and equipment with significant vibration and impact. The motor has good sealing |

| Buffers and limit switch |  | The buffers has the good performance of absorbing the energy of the motion mechanism and reducing the impact The crane and trolley operating mechanisms are equipped with travel limit switches. When running to the limit position, it can automatically cut off the power supply and send out a signal. |

CONTACT

Be the first to know about our new product releases and latest news articles.Do you have any questions or requests?

Click below and we'll be happy to help. CONTACT